Investigating the Potential for Producing Mango Fruit Powder at the Farm Level in India

===========================================================================

In an effort to boost income, reduce waste, and meet the rising global demand for natural mango-based products, India, the world's largest producer of mangoes, is exploring farm-level production of mango fruit powder. This innovative approach can provide farmers with an additional revenue source while helping to increase the overall value of mango produce.

To establish farm-level mango fruit powder production, the key steps include:

Mango Cultivation and Raw Material Preparation

- Select suitable soil and location with low salinity and proper drainage; prepare pits (1m deep and diameter) filled with topsoil and manure for planting.

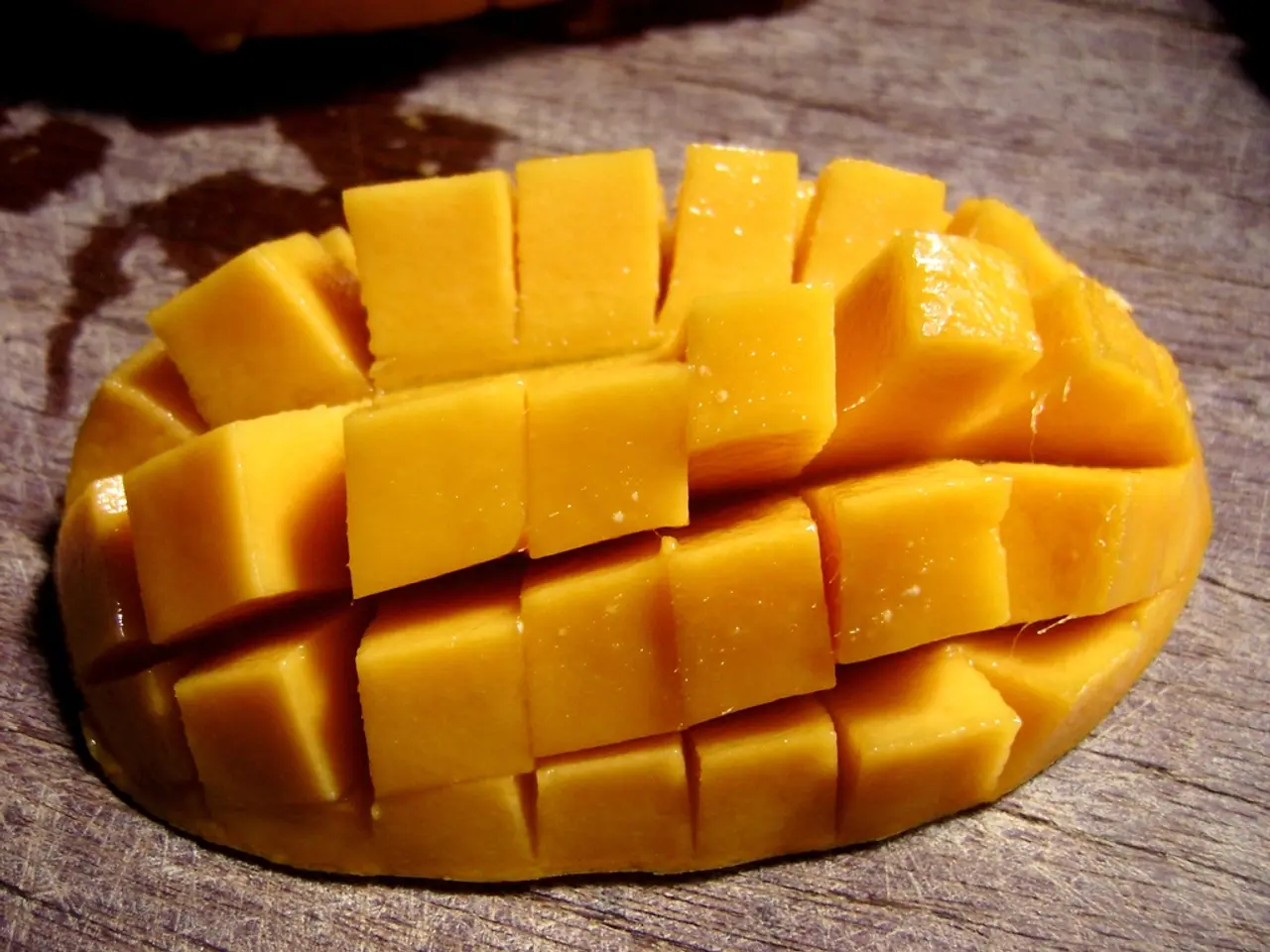

- Ensure healthy mango fruit harvesting with proper ripening stages for optimal quality.

- Use mechanized mango peeling machines to reduce labor and improve efficiency.

Processing Steps

- Wash and sort mango fruits to remove dirt and defective pieces.

- Slice or pulp the mangoes for drying; popular and eco-friendly drying methods include sun-based drying, spray drying, cast-tape drying, or drum drying.

- Powder the dried mango slices or pulp using grinding and sieving machines to obtain fine mango powder with uniform particle size.

Machinery and Infrastructure

- Essential equipment includes washing and sorting units, dryers (spray dryers, drum dryers, or freeze dryers), grinding machines, sieving and packaging machines.

- Power and water supply must be steady with backup systems to avoid downtime.

- Waste management systems to handle peelings and wastewater in an environmentally friendly way.

Packaging and Storage

- Use automated or semi-automated packaging to seal powder with moisture-proof packaging to maintain shelf life.

However, challenges do arise in this venture. High initial investment for machinery can be mitigated by opting for semi-automatic systems initially and seeking government subsidies or farmer cooperatives for funding. Consistent quality and standardization can be achieved by sourcing mangoes from trusted suppliers and using standardized drying and powdering methods. Power and water reliability can be ensured by installing backup power systems and water treatment plants. Post-harvest losses and hygiene can be minimized by using mechanized peeling and sorting machines. Maintaining nutrient content can be achieved by choosing drying methods like spray drying or cast-tape drying that preserve antioxidants and nutrients.

Integrating natural biological inputs such as biofertilizers can enhance mango orchard productivity sustainably.

Farmers can also improve their market access by joining cooperatives or farmer-producer organizations (FPOs). Adopting the production of mango fruit powder at the farm level can boost farmers' incomes, reduce waste, and cater to the growing demand for natural mango-based products.

It's worth noting that mango fruit powder has a longer period of viability compared to fresh mangoes, making it an attractive option for various industries, including food, cosmetics, and pharmaceuticals. The demand for mango fruit powder is growing, driven by a preference for natural and traditional products.

Farm-level production of mango fruit powder can help farmers expand their market reach beyond local markets, providing them with the opportunity to tap into the global market for natural mango-based products. With the right approach, this innovative venture can prove to be a game-changer for Indian farmers.

Training and workshops provided by farming colleges, NGOs, and government organizations can help farmers develop the necessary skills for management and quality control. By following these guidelines, farmers can successfully establish farm-level mango fruit powder production and reap its numerous benefits.

The innovative approach of farm-level production of mango fruit powder can potentially attract investments from the finance industry, as it offers farmers an additional revenue source and contributes to reducing waste in the food-and-drink industry. This business venture, if successfully established, can significantly impact the lifestyle of farmers by improving their income and livelihood. Furthermore, the growing demand for natural mango-based products in various industries such as food, cosmetics, and pharmaceuticals presents a potential market for farm-produced mango fruit powder, thereby opening up opportunities for international trade and exports.